The Future of Home Sealing: What It Means to 'Seal It' in 2024

Have you ever walked from one room to another in your Maine home and wondered why one room feels like a cozy blanket while the other feels like you've stepped into a freezer? That's a classic sign of an unsealed home. It's not just about the chill; it's about the comfort of your entire space being even and predictable. Figuring out if your home is sealed properly is about knowing what to look for and where to look.

Key Areas to Seal with Spray Foam Insulation: A Comprehensive Guide

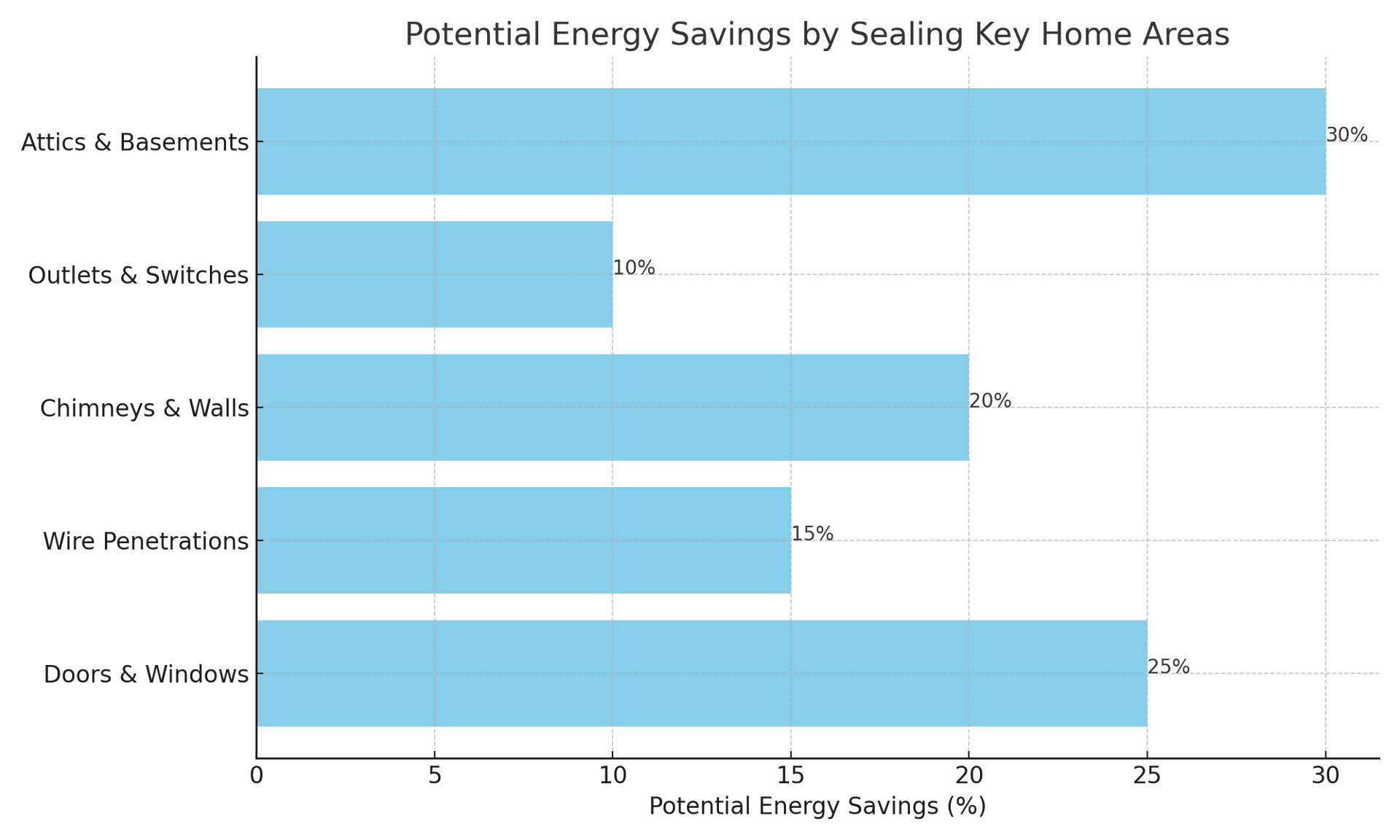

1. Doors and Windows: The Frontline Defense

Doors and windows, while essential for ventilation and natural light, are also prime areas for energy loss in any home. Traditional weather stripping can wear out, and gaps can develop over time, particularly in older homes. Spray foam insulation offers a durable solution by expanding to fill cracks and crevices around these openings, creating an airtight seal that prevents air leakage, enhances energy efficiency, and reduces heating costs.

2. Wire Penetrations and Plumbing: Precision Sealing

The numerous small openings around wires and plumbing fixtures might seem insignificant but are crucial points for air leakage. Spray foam insulation is particularly suited for these areas because of its ability to expand and fill even the tiniest gaps. This ensures a comprehensive seal that blocks cold air from entering and warm air from escaping, addressing these overlooked details with precision and effectiveness.

3. Chimneys and Exterior Walls: Structural Integrity

Chimneys and exterior walls can present significant challenges for maintaining a warm and sealed home environment. Spray foam insulation not only seals gaps and cracks in these large areas but also adds structural integrity. For chimneys, especially, applying spray foam insulation around the base where it meets the roof can prevent warm air from escaping and stop drafts from entering. On exterior walls, spray foam can fill in the porous spaces in the masonry or between siding and the wall structure, blocking cold air penetration and improving thermal retention.

4. Electrical Outlets and Switches: The Unseen Leaks

Electrical outlets and switches on exterior walls are often ignored sources of heat loss. Spray foam insulation can be carefully applied around these fixtures to fill the spaces between the wall and the outlet boxes, effectively stopping cold drafts. This application is especially beneficial in preventing the unseen leaks that contribute to a cooler home environment, ensuring that warmth stays inside where it belongs.

5. Attics, Basements, Box Sills, and Rim Joists: Comprehensive Coverage

Attics and basements, along with box sills and rim joists, represent critical areas for heat retention and moisture control. Spray foam insulation provides a superior solution for these spaces by offering comprehensive coverage. In attics, it can be applied directly to the underside of the roof and floor to seal off air leaks and prevent heat from escaping. In basements, box sills, and rim joists, spray foam not only insulates but also creates a moisture barrier, protecting against dampness and mold, which traditional insulation methods cannot offer.

Spray foam insulation stands out as the most effective way to seal and insulate your home, addressing all the critical areas where heat loss occurs. By choosing spray foam, you're not just insulating; you're investing in an energy-efficient, comfortable, and healthier home environment. Ready to enhance your home with spray foam insulation? Contact us today for a consultation and see how you can benefit from this superior insulation solution.

Uncovering Hidden Leaks: Advanced Detection Techniques

In the quest for a fully sealed and efficient home, the combination of thermal imaging cameras and blower door tests stands as a formidable duo for identifying leaks that are invisible to the naked eye. Let’s dive deeper into how these tools work together to pinpoint the areas in your home that are most in need of spray foam insulation.

Thermal Imaging Cameras: Visualizing the Invisible

Thermal imaging cameras operate by detecting the temperature differences around your home, translating them into visual data. This technology allows you to "see" the cold spots - areas where cold air is infiltrating your home and warm air is escaping. During the inspection, these cameras highlight the problematic areas in distinct colors, with cooler areas typically shown in blue and warmer areas in red. This color-coded visual guide is invaluable in understanding how well your home is insulated and where improvements are necessary. It's especially effective around known problem areas such as windows, doors, and other notorious leak spots, providing a clear picture of where your home is losing energy.

Blower Door Tests: Creating a Controlled Environment

A blower door test takes the process of identifying leaks one step further by creating a controlled environment to enhance the accuracy of thermal imaging. This test involves fitting a powerful fan into the frame of an exterior door. Once activated, the fan pulls air out of your home, lowering the indoor air pressure. As a result, higher pressure air from outside rushes in through all unsealed cracks and openings.

Setting up a blower door test requires the home to be prepared adequately. All windows and doors must be closed, and any heating or cooling systems turned off to ensure accurate results. The setup includes sealing the fan into an exterior door frame using adjustable frames and tightly fitting cloth panels to ensure air is drawn solely through the fan, maximizing the change in interior air pressure.

The Combined Effect: A Comprehensive Leak Detection System

When used in conjunction, thermal imaging during a blower door test becomes even more effective. The lowered pressure inside the home accentuates the entry of cold air through leaks, making them more detectable by the thermal camera. This process not only reveals the obvious leaks around doors and windows but also uncovers the less apparent ones, such as those around electrical outlets, light fixtures, and in attic or basement areas that are rarely inspected.

By visualizing these leaks, homeowners can create a targeted plan for applying spray foam insulation, focusing on the areas that will provide the most significant improvement in energy efficiency and comfort. This approach ensures that every dollar spent on insulation delivers maximum value, making your home warmer in the winter, cooler in the summer, and more energy-efficient year-round.

In summary, utilizing thermal imaging cameras and blower door tests offers a scientifically advanced, yet surprisingly straightforward method to identify where your home needs sealing. This process ensures that spray foam insulation can be applied in the most effective way, sealing off the drafts and leaks that lead to energy loss and discomfort, paving the way for a sealed, more energy-efficient home.

Sealing the Deal with Savings

Efficiency Maine Rebate Program

Here's some good news for Maine residents: the Efficiency Maine program offers rebates that cut the cost of insulating your home by 40-80%. These funds aren't endless, though, so the time to act is now. Making your home snug and saving money? It’s a win-win.

| Insulation Area | Approx. Cost Before Rebate | Estimated Rebate (%) | Cost After Rebate |

|---|---|---|---|

| Attics | $2,500 | 40-80% | $500 - $1,500 |

| Basements | $2,000 | 40-80% | $400 - $1,200 |

| Exterior Walls | $3,000 | 40-80% | $600 - $1,800 |

| Rim Joists | $1,000 | 40-80% | $200 - $600 |

| Total Home Seal | $8,500 | 40-80% | $1,700 - $5,100 |

Take Action Today

Ready to stop the drafts and start saving? Fill out our get-started form or call us at 207-777-6020 for a free estimate and to see if you’re eligible for the Efficiency Maine rebates. Don’t wait until the cold hits - make your home cozy and efficient for 2024 now.